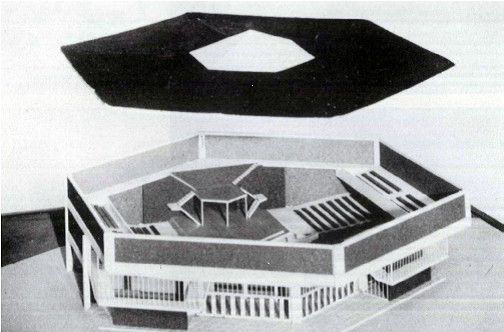

Chichester Festival Theatre boasts the first suspension roof anywhere in the UK. It is this feature of the building that means all of the seats in the auditorium have uninterrupted views of the stage.

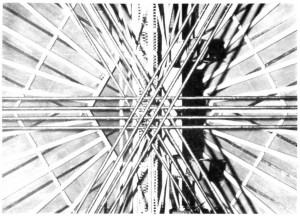

Four pre-tensile steel cables run between the tops of the concrete pillars at each point of the Festival Theatre hexagon, holding this building together. Driven right through the concrete, they pull opposite columns together and can clearly be seen just below the ceiling inside the auditorium. They counter the forces from the roof and the walls of the auditorium pushing down and outwards. They also bear the weight of the part of the auditorium that is cantilevered over the Theatre entrance, pushing strongly outwards and down.

The process of installing the cables would have been a hair-raising experience; the cast concrete of the columns and the ring beam had been poured on-site into wooden form-work, like molds, held up by scaffolding – or props. While the concrete was still in this form-work, the cables were passed through the columns and then cranked tight till they took the weight of the building. The four black bolts you can see near the top of each of the six columns supporting the Theatre are the ends of these steel rods. It was only when the form work was removed that these cables had to take the buildings full weight and the team knew for sure that the structure worked. Christopher Stevens was a young architect working at Powell and Moya at the time and had been given day to day responsibility for Chichester Festival Theatre. He made a point of standing underneath the cantilever as this form-work was being removed.

The building was then left to rest which meant it was left to move slightly, as all new buildings do, under its own weight. The cables had to be re tightened a number of times because of this natural shifting. The strain that these cables are under can clearly be seen, they are being pulled in with such force that they lean inwards slightly at the top.